BMW’s Valvetronic system is a groundbreaking technology that represents a significant leap forward in internal combustion engine design. Working in tandem with the VANOS system, which controls valve timing, Valvetronic provides continuously variable control over intake valve lift. This innovation not only enhances engine performance and fuel efficiency but also fundamentally changes how the engine breathes, largely eliminating the need for a traditional throttle body.

The Problem with Traditional Throttles

In a conventional gasoline engine, the driver’s pressure on the accelerator pedal controls a throttle plate, a butterfly valve that regulates the amount of air entering the engine. While effective, this system has a significant drawback known as “pumping losses.” When the throttle is only partially open, the engine’s pistons must work harder to draw air through the restriction, wasting energy and reducing efficiency. This is particularly prevalent during city driving and at low engine loads.

The Valvetronic Solution: Throttling with the Valves

Valvetronic ingeniously solves the problem of pumping losses by eliminating the traditional throttle plate’s primary role in air management. Instead of restricting airflow at the intake manifold, Valvetronic controls the amount of air entering the cylinders by directly adjusting the lift of the intake valves. This means the engine can breathe more freely, significantly reducing pumping losses and improving fuel economy, particularly in everyday driving conditions.

How It Works: The Mechanical Brilliance

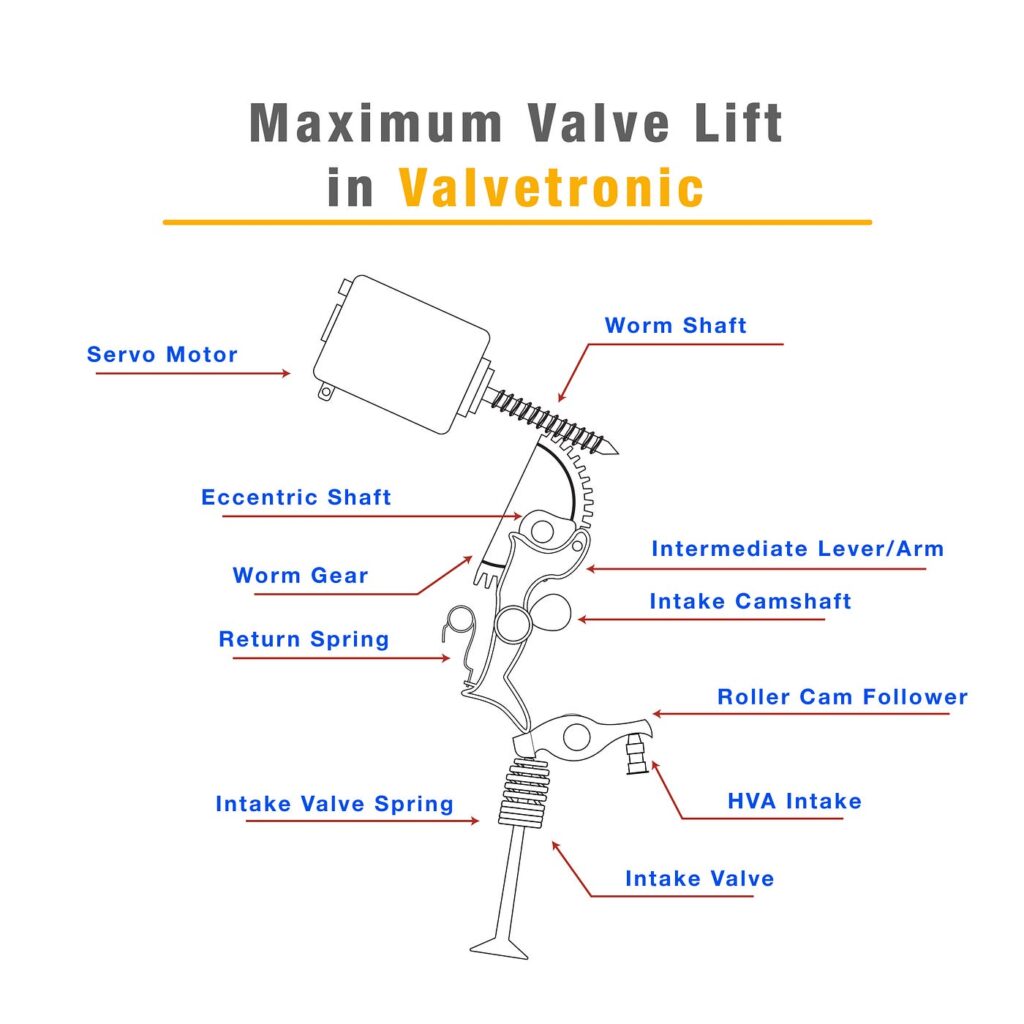

The core of the Valvetronic system is a sophisticated mechanical linkage that adds an extra layer of control to the valvetrain. Here’s a step-by-step breakdown of its operation:

1.

The Eccentric Shaft: The system’s key component is an additional, electronically controlled eccentric shaft. This shaft is actuated by a high-speed electric servomotor.

2.

The Intermediate Lever: Positioned between the camshaft and the intake valve’s rocker arm is an intermediate lever. The eccentric shaft acts on this lever, changing its pivot point.

3.

Variable Valve Lift: By rotating the eccentric shaft, the servomotor alters the position of the intermediate lever. This, in turn, changes how the camshaft’s lobe interacts with the rocker arm, ultimately varying the distance the intake valve opens (its lift). When the driver demands more power, the servomotor rotates the eccentric shaft to increase valve lift, allowing more air into the cylinders. When less power is needed, the valve lift is reduced.

Key Components and Their Roles

A clear understanding of the Valvetronic system requires familiarity with its primary components:

| Component | Role |

| Eccentric Shaft | An electronically controlled shaft that, when rotated, adjusts the pivot point of the intermediate lever. This is the core actuator for varying valve lift. |

| Servomotor | A high-speed electric motor that precisely rotates the eccentric shaft based on commands from the engine control unit (DME). |

| Intermediate Lever | A lever positioned between the camshaft and the rocker arm. Its position, dictated by the eccentric shaft, determines the amount of lift transferred to the valve. |

| Rocker Arm | Transfers the motion from the intermediate lever to the intake valve, causing it to open. |

| DME (Digital Motor Electronics) | The engine’s computer, which orchestrates the entire process. It analyzes driver input, engine speed, and other parameters to determine the optimal valve lift and instructs the servomotor accordingly. |

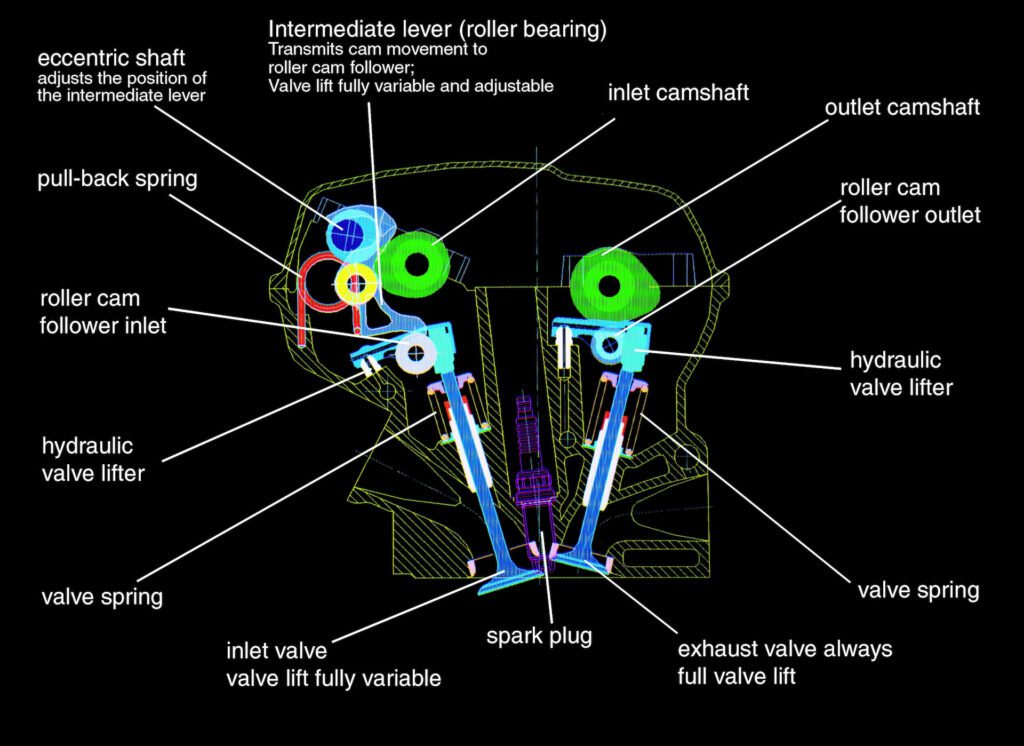

A detailed view of the Valvetronic assembly, showing the intricate relationship between the components.

The Synergy with VANOS

Valvetronic does not work in isolation. It is paired with BMW’s VANOS (Variable Nockenwellen Steuerung) system, which is responsible for varying the timing of the intake and exhaust camshafts. This combination is crucial for optimizing engine performance across the entire RPM range:

•

Valvetronic controls how much the intake valves open (lift).

•

VANOS controls when the intake and exhaust valves open and close (timing).

Together, these two systems provide complete control over the engine’s breathing, allowing the DME to fine-tune the combustion process for maximum power, efficiency, and minimal emissions under all operating conditions.

Benefits of Valvetronic

The implementation of Valvetronic technology yields several significant advantages:

•

Improved Fuel Efficiency: By minimizing pumping losses, Valvetronic can improve fuel economy by 10% or more in typical driving scenarios.

•

Enhanced Throttle Response: With Valvetronic, the engine responds more directly and immediately to the driver’s input, as there is no delay associated with waiting for air to fill the intake manifold after a throttle plate opens.

•

Lower Emissions: The precise control over the air-fuel mixture and combustion process results in cleaner emissions.

•

Improved Cold-Start Performance: The system allows for more stable engine operation and faster catalyst warm-up during cold starts.

In conclusion, BMW’s Valvetronic system is a testament to the brand’s commitment to engineering excellence. By rethinking the fundamental principles of engine airflow management, BMW has created a system that delivers a more efficient, responsive, and cleaner driving experience.